Analytics

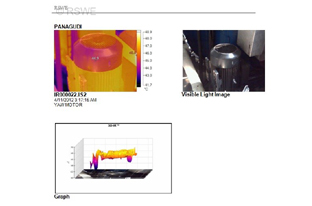

Vibrations, Thermography and Oil analysis:

Specialized vibrational analyzer are used to analyze and evaluate vibrations of the tower and major components when the WTG is operational. A Thermographic instrument with thermal imaging cameras is used to record temperature variations in critical electrical and mechanical components. Oil samples are taken from the Gearbox and tested in the labs for physical and chemical properties. The above inspections give the accurate condition of the wind turbine and help prevent major breakdowns.

Borescope inspections:

Reach and detect defects without opening the gearbox through a high resolution boroscopic cameras inserted into the inspection holes. The photographed images can be viewed for detecting conditions of the Gearbox internals, Generators and Main bearings. We carry out this exclusive inspection on request and submit the reports with detailed image documentation of our recommendation to the clients of the above The conditions of the internals are checked by physically for abnormalities while some of the repairs and replacements can be carried out on tower itself, when absolutely necessary the gearbox will be brought down to the workshop for the repair and overall.

Ultrasonic Test:

RS Windtech perform UT inspection from hub side and inside nacelle of main shaft by using probe of 45 degree and zero degree. The 45 degree probe used for main shaft plumber block area. Maximum we can scan up to 8 meter length main shaft.

Tower Inspection:

The exercise covers thorough inspections of the civil foundation structures, Bolts from bottom to Nacelle for prescribed rigidity, Check for cracks in weld joints of tower shells and interior and exterior paint damage and corrosion. Checking the ladder and platform support brackets. Checking of Lighting cables, Junction boxes and power cables. Also annually we check for any offset in tower through water level

The periodical inspections of the above is essential for the sustained strength, longevity of the tower and ultimately the performance of the WTG in power generation.

Nacelle Inspection:

RS Windtech perform inspection inside nacelle for the running healthiness of components like generator, gear box, main bearing, yawing system, brake unit, coupling, wind vane, anemometer etc,. Also we check the oil spillage inside the nacelle and electrical wirings.

Blade Inspection:

The state of blades is important for the optimal operation and power generations of wind turbine and prevention of potential breakdowns. Blades are highly expensive and time consuming to repair. We perform blade inspection by hoisting platforms, Drones and Binocular from ground for cracks and damages. On request from clients we provide the service and submit our recommendations with photos on the condition of wind turbines components.

Unit Sub Station:

Checking of Lightning arrestors, AB Switches, All insulators, Connections of Copper bus bars, Earth pit condition and earth values, Checking of Breather, Oil levels, HT& LT Bushes, Radiators of transformers

Regular technical inspections of the USS covering all the above is extremely important in the context of statutory safety regulations preventing untoward incident and grid connectivity to the WTG of the recording of power generation. Rule 46 inspection report compliance every 2 years